AIR

Atmospheric Emissions

LAV has thirty years’ experience in characterisation sampling and testing of atmospheric emissions originating from

multiple industrial processes.

Our laboratories have modern sampling lines that are maintained at full efficiency, to meet the requirements of each relative

standard and UNI EN ISO 17025.

Our Experts are constantly updated on legislation, technical regulations and courses, so that they can carry out their work

in complete safety. An incomplete list of the parameters that can be monitored is provided below:

- Capacity

- Oxygen, Carbon Dioxide, Nitrogen and Sulphur Oxides

- Particulate Matter

- Fraction PM10, PM2.5 respirable dust

- SOV

- Total Organic Carbon

- Metals

- Inorganic Acids

- Aldehydes

- Amines

- Sulphur Compounds

- PAHs

- PCDD/PCDF

- PCB

Mathematical models of pollutant dispersion and deposition can also be formulated.

Work Hygiene

LAV laboratories have several years’ experience in characterising chemical, physical and microbiological agents in working

environments. Data obtained from monitoring can be processed into technical reports, to make them easier to use.

Chemical Agents

Aerodispersed chemical agent monitoring campaigns, planned and conducted in compliance with the contents of the StandardUNI EN 689:2019.

The obtained data can be processed on specific spreadsheets, to evaluate observance of personal exposure limits for

individual SEG (Similar Exposure Groups) in observance of the requirements contained in the Standard UNI EN 689:2019.

Microbiological Agent

Identification of aerodispersed and surface microbiological contamination (bacteria, fungi, Legionella, etc)

Physical Agents

Measurements of the following physical agents are taken using certified, technologically-advanced instruments:

- Noise

- Vibrations

- Light

- Electromagnetic Fields

- Artificial Optical Radiation

- Ionising Radiation

- Microclimate

- Radon

Environmental Air Quality Monitoring

Environmental monitoring to characterise external air quality, for comparison with the reference values contained in Legislative Decree 155/2010. The following parameters can be monitored:

- Meteorological parameters (Temperature, Humidity, Precipitation, Wind Speed and Direction)

- Total Particulate Matter

- Fraction PM10, PM2.5 PM1 particulate matter

- Nitrogen Oxide (NOx, NO2)

- Carbon Monoxide (CO)

- Ozone (O3)

- PCB

Contaminated Sites

For the characterisation of contaminated sites, the LAV laboratories offer a wide range of services as required by the SNPA 15/2018 Guidelines, such as:

- Draining, sampling and SGS testing in compliance with the indications provided in Annex A.

- Check using hood and trace GAS (Helium) of SGS seals installed previously (Leak Test). This check is conducted prior to Soil Gas sampling.

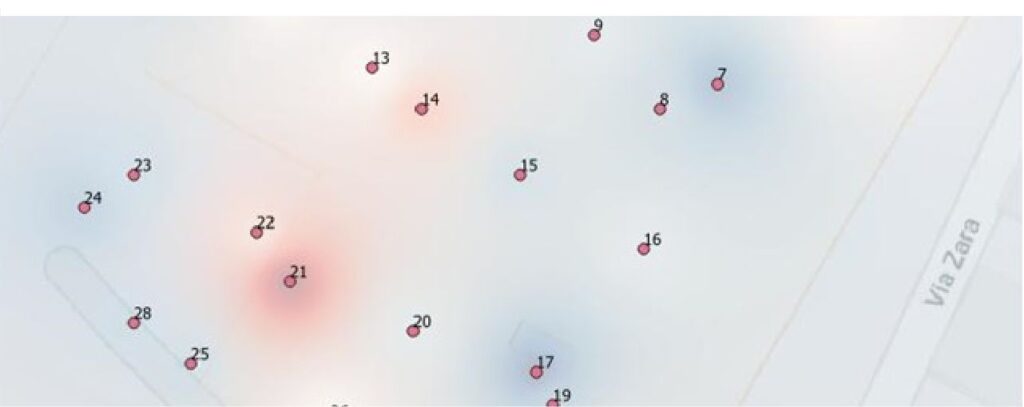

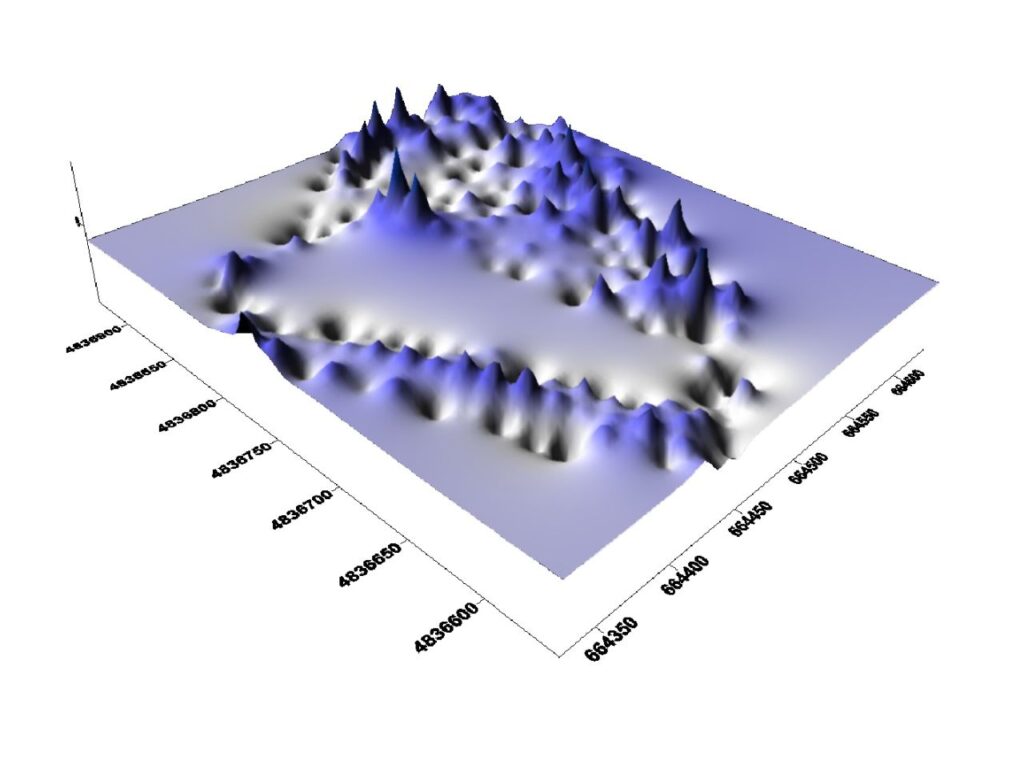

- Estimation of CO2 and COV isoflows from sites being characterised, using accumulation chambers in the field followed by GIS processing of the resulting data.

- Sampling via DYNAMIC OPEN FLUX CHAMBERS of soil gases in compliance with the contents of Annex B.

Testing methods and the detection limits for each analyte are compliant with the contents of the SNPA 16/2018 Guidelines. A conversation with our specialised technicians is essential in order to find the best solution for correct monitoring.

Flux Chamber

Should local hydrogeological situations not permit direct measuring of soil gas by using probes inserted into the ground, the interstitial gases can be monitored instead, using a flux chamber. Flux Chamber monitoring entails an estimation of the gas/vapour flow in terms of mass per surface unit in the unit of time (μg/m2*min). The flux chamber isolates a part of the area from external environmental conditions (wind, pollutants). Using this instrument is reliable for measuring Volatile Compounds at the earth-air interface.

Our flux chamber is open-dynamic. The open-dynamic flux chamber consists of injecting a constant carrier gas (Nitrogen 5.0) flow into the Flux Chamber through a distribution tube that ensures its even distribution inside the chamber. The chamber is placed on the ground and sealed by a 5cm-layer of damp sand or dry bentonite around its base. Before actual sampling, “draining” of at least 4 times the volume of the chamber is required, to eliminate the air and achieve perfect soil gas mixing conditions inside the chamber. The following parameters are recorded at regular intervals during draining: Internal and external chamber temperature, concentrations of O2 (%), CO2 (%), CH4 (%), COV (ppm), and ΔP (Pa) between inside and outside of chamber, and also atmospheric pressure.

Sampling is conducted using a hollow road that extends along the entire height of the flux chamber, so that the entire volume can be sampled. It is connected to one of more sampling lines via the outlet. The utmost attention must be paid so that the incoming Nitrogen flow is always higher than the total sampling flow. The concentration of substances searched for in the soil gas can be monitored continuously using analytical field instruments (PID – FID – GC/MS) or by chemical desorption ampoules, thermal desorption ampoules, colorimetric ampoules, Tedlar bags, canisters, etc An incomplete list of the substances that can be searched for using this sampling technique is as follows: Aliphatic Hydrocarbons, Aromatic Hydrocarbons, Halogen Hydrocarbons, Nitrogen Hydrocarbons, Sulphur Compounds, Aldehydes and Ketones, Mercury, Tetraethyllead, Phenols, Cresols, Ammonia, Amines, PAHs, H2S, Pesticides, PCB.

Landfill Sites - Diffuse Emissions

Mapping via landfill bed outgoing biogas accumulation chamber. This type of mapping is carried out using a portable flow meter, which measures emissions from the ground based on the accumulation chamber principle, using static not stationary technique. The instrument in question has CO2, CH4, H2S and VOC sensors and continuously measures gas concentrations inside a specific accumulation chamber to obtain an immediate evaluation of the increase rate of said gases. Compared to other methods, the flow meter described can determine flows of CO2, CH4, H2S and VOC from the ground regardless of whether the land characteristics and flow regime are known or not. In fact, no empirical coefficients linked to the land’s characteristics are used to determine flow.

Olfactometry

laboratories are equipped with specific instrumentation for sampling the different odorous sources. Therefore, they can be monitored, in accordance with what is reported in the national reference guidelines:

- Active air sources (pyramid-shaped hood)

- Passive liquid and solid air sources (open dynamic Flux chamber, Wind Tunnel)

- The samples for olfactometric sampling are collected in Nalophan bags using a vacuum sampling pump thatintroduces the air sample directly into the bag without any risk of cross contamination.

- Continuous odour monitoring systems can be installed, such as electronic noses and automatic odour and other specificsubstance sampling systems.

A conversation with our specialised technicians is essential to find the best solution for correct monitoring.

Indoor Monitoring

Indoor monitoring to determine chemical, physical and microbiological agents, with production of specific monitoring protocols.

Monitoring can be carried out in rooms or air delivery installations (UTA) to assess function and efficacy of the maintenance service.

Technical inspections can also be conducted on primary air distribution plants.